Do my motorcycle’s injectors need cleaning?

Fuel injector cleaning is even more important on your motorcycle than it is for your car. To understand why let’s talk about all the things it accomplishes.

What Does Fuel Injector Cleaning Do?

First, we want to say when we’re talking about fuel injector cleaning we aren’t talking about removing your fuel injectors and getting them professionally cleaned immediately. If your motorcyclye has been well maintained you may be able to simply add some fuel injector cleaner to your gas tank next time you fill-up.

Reduces the Possibility of Knock

One of the biggest things keeping your fuel injectors clean can accomplish is reducing the possibility of knock. Knock, or pre-ignition is when the air/fuel mixture detonates before the spark ignites it. Knocking can cause severe engine damage and can happen if you don’t have the right air-fuel mixture. A dirty fuel injector can have poor atomisation which in severe cases can cause knocking itself but more often leads to an incomplete burn and a dirty combustion chamber. A dirty combustion chamber increases the compression ratio which can also lead to knocking and engine damage. Keeping your fuel injectors clean can help reduce this possibility.

Constant Fuel Pressure

Your bike’s fuel injection system runs off the assumption that fuel pressure is constant, usually 35-50 PSI. If fuel pressure changes drastically it will affect the motor’s ability to run correctly. Low fuel pressure can lead to a lean condition which can cause extremely high cylinder temperatures and possible engine damage. Using fuel injector cleaning agents can reduce deposits in the fuel system as well as helping keep fuel pressure constant.

Improves Engine Balance

Lastly, clean fuel injectors will lead to a balanced engine. If each injector is delivering the same amount of fuel your engine will run smoothly. If an injector is clogged and delivering less fuel your engine’s computer will increase fuelling in the other cylinders leading to an imbalance. Besides heat build-up, this also creates a motor that won’t idle smoothly as well as vibrations. Vibrations are the killer of all things and can shorten the life of your motor.

Motorcycle engines are high-performance motors and are built to run at the edge more so than the engine in your car. This extra performance increases responsiveness and the power to weight ratio of your motorcycle but it also makes your engine much more prone to the issues we’ve talked about above.

Your engine is also built from lightweight high-performance materials that won’t hold up under poor operating conditions like knocking or imbalances, so it’s even more important to make sure everything is working properly. If your motorcycle has been sitting for months, it’s even more important to make sure your fuel system is 100%.

Fuel Injector Ultrasonic Cleaning & Flow Testing

BikeTech Performance offers a complete cleaning and flow testing service for your fuel injectors.

Electronic Fuel Injection is now fitted as standard equipment on virtually every street motorcycle produced. There is no equipment currently available that will enable a technician to accurately analyze the condition of the fuel injectors while they are on the motorcycle. This makes it impossible for any technician to correctly and accurately diagnose faults, or make adjustments to a fuel injection system. The BikeTech Performance Fuel Injector Cleaning & Flow Testing service will ensure that you are starting with properly working injectors that flow a known amount.

The Injector Valve has the finest tolerances of any mechanical component in an engine.

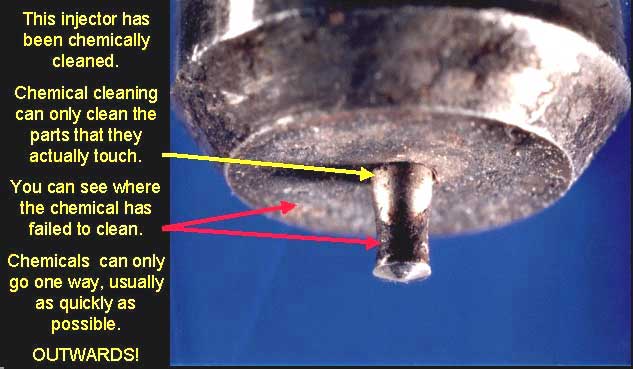

Heat Soak is the biggest cause of fuel injector problems. Heat Soak occurs when the pintle is hot and the engine is turned off. A small amount of residual fuel remains on the pintle end of the injector.

The heat from the engine evaporates this residual fuel leaving microscopic layers of lacquers, waxes and varnishes from the fuel’s chemical additives on not only the tip and seats of the injector but also onto the inner walls. This drying process produces a fine layer of hard, “baked on”, difficult to see and difficult to remove chemical coating.

A small amount of this coating can affect the travel and seating of the pintle. which in-turn will affect fuel delivery, fuel distribution and atomization, resulting in combustion related problems.

With the latest generation of engine management systems, a matched, balanced set of injectors is critical to an engines correct performance and operation.

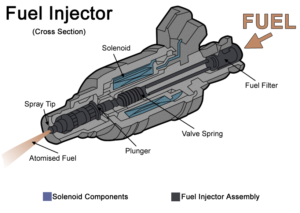

Injector schematic

For those of you who are interested…